The Sheroz Earthworks Ideas

The Sheroz Earthworks Ideas

Blog Article

Sheroz Earthworks Fundamentals Explained

Table of ContentsWhat Does Sheroz Earthworks Do?The Best Guide To Sheroz EarthworksThe Main Principles Of Sheroz Earthworks The smart Trick of Sheroz Earthworks That Nobody is Talking AboutSheroz Earthworks Things To Know Before You Get ThisMore About Sheroz Earthworks

Today, Smart Construction Remote links over 700 equipments on jobsites to workplaces, conserving thousands of hours previously invested by jobsite managers, surveyors and engineers travelling from offices to jobsites. To summarise, the initial 10 years of Komatsu's smart equipment control have actually been noted by a years of special innovation, continual learning and development with consumers.

Below's to the following 10 years! Web content generated in organization with Komatsu.

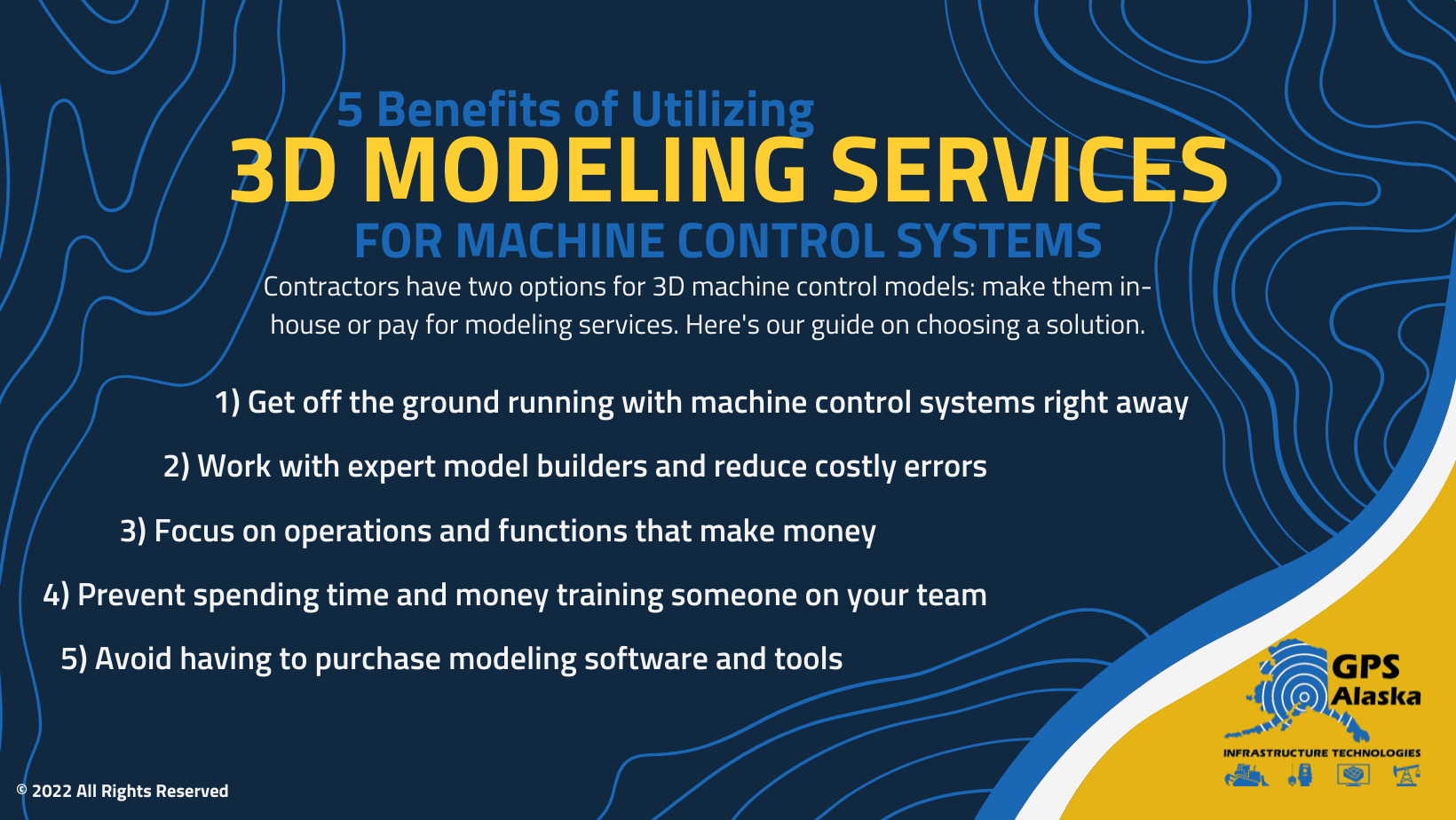

In the quickly progressing world of building, precision and efficiency are essential. 3D equipment control, a system that makes use of general practitioner and other sensors to guide equipment with determine precision, is revolutionising the industry - https://www.wattpad.com/user/sherozau. From its very early days of 2D assistance, this modern technology has progressed considerably, making tasks that when required hands-on treatment now possible with marginal human input

In building, it makes certain that every cut, fill, and quality is performed with surgical accuracy. Allow's discover how this game-changing innovation works. At the core of any kind of 3D machine control system are GNSS receivers and antennas, capturing satellite signals to establish the machine's precise place. Onboard computer systems and control boxes procedure this information and communicate with the machinery.

Some Of Sheroz Earthworks

This consists of establishing up GNSS receivers, calibrating sensing units, and configuring the machine control software program - topcon. The magic of 3D equipment control exists in its real-time data collection and processing.

User user interfaces supply real-time updates on the device's position and essential modifications, guaranteeing specific control. In building, 3D device control is made use of for earthmoving, grading, paving, and excavation, making sure jobs are completed to specific specs.

The Basic Principles Of Sheroz Earthworks

3D device control substantially increases effectiveness by minimizing rework and minimising material wastage, resulting in faster and more economical task conclusion. The modern technology makes certain every job is carried out specifically as intended, leading to continually top quality work. Among one of the most engaging advantages of 3D equipment control is the significant price savings it provides.

Gas intake is optimized because devices run better and stay clear of unnecessary motions. Upkeep costs are also decreased, as the equipment experiences less deterioration due to precise operation. Overall, these savings add to an extra profitable profits for any kind of task. By minimizing human error and restricting exposure to unsafe atmospheres, 3D machine control boosts worker safety and security and decreases crashes.

From building to mining, this modern technology guarantees jobs are executed precisely and securely, decreasing useful reference expenses and boosting outcomes. As advancements proceed, the possibility for 3D device control to additionally enhance performance and safety grows. Embracing this innovation is essential for sector professionals seeking to remain competitive and attain the highest criteria in their projects.

The Ultimate Guide To Sheroz Earthworks

Discover the future of precision and effectiveness currently! Inspect out our newest YouTube video on the FJD H36 Electric Motor Grader Control System to see the modern technology in action: Watch now.

Over the years, we've seen drivers with whole lots of experience do some amazing points with their makers. Perhaps they have an eye for adjustments that improve accuracy, or maybe they understand which features of their machine to make use of and when to enhance performance or performance - https://www.giantbomb.com/profile/sherozau/. However with today's innovations in hefty tools technology, even knowledgeable operators can take advantage of a real-time assist to improve their everyday performance (fj dynamics auto steer price).

This is where device control systems element in. Some excavators come with maker control systems that lead the driver through functions to automate the digging procedure.

About Sheroz Earthworks

With this added accuracy, rework is basically eliminated, enabling the driver to finish the task on time and move to the following task. For those working on harmful or hard jobsites, remote-controlled options open brand-new possibilities. This impressive add-on enables you to run an excavator from a range in locations with hazardous materials (like in a potash mine) or poor ground problems (like mud).

Equipment control systems offer beneficial advantages to more than just excavator drivers. If you have a truck come in with a target of 23 tons, your driver can fill their bucket and dynamically consider itoften without also being stationary.

This means the operator can see the exact weight of the load they will discard (topcon gps). On-board evaluating offers real-time insight into the bucket's load to make overloading, underloading, reweighing and waiting times a distant memory. Volvo Building and construction EquipmentIf they dump 12 loads on the initial pass, the following bucket requires to evaluate 11 bunches

Our Sheroz Earthworks PDFs

Many procedures utilize an on-board weighing app to make certain that the tons is exact before they send their vehicles to the ranges, which is essential due to the fact that the scale weight is what's used for invoicing and invoicing purposes. Numerous producers consist of some sort of considering program on their loaders. Some additionally have functions that permit firms to monitor and regulate the complete lots of numerous trucks.

Report this page